Application

A razor’s cutting ability depends on the condition of the blade edge, and a chipped blade makes the razor dull. When testing a blade’s durability, it is important to correctly capture the shape of the blade edge for quality improvement. However, due to the blade edge’s extremely acute angle, it is difficult to capture accurate images of the edge’s shape.

The Olympus solution

Olympus' LEXT 3D scanning laser microscope has a very high detection sensitivity for slopes, enabling three-dimensional observation and measurement of the small shape of a razor blade edge. By comparing new and used blades, you can visually check edges whose sharpness has deteriorated, and the high-resolution and high-precision 3D shape m\easurement enables you to quantitatively evaluate the angle of the edge and the depth of chipping.

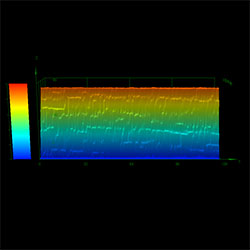

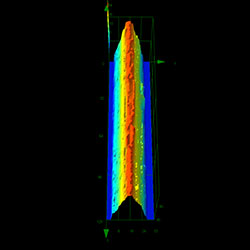

Non-defective blade edge | |

|

|

|

Objective lens: 100X Zoom: 1X

| |

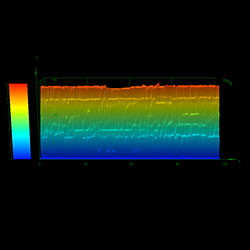

Chipped blade edge after use | |

|

|

|

Objective lens: 100X Zoom: 1X

| |