Interest in cobalt exploration has increased significantly due to growing demand for this specialty metal. Traditionally used in high-temperature alloys, cobalt now plays an important role as a critical component of lithium-ion batteries used in electric vehicles (EVs). Growth in electric vehicle sales is driving a significant increase in the price and demand for cobalt. The industry is also seeking to diversify its supply sources, as estimates show between 60–80% of cobalt is sourced from the Democratic Republic of Congo (DRC) and refined in China.

In nature, cobalt occurs within a diverse range of minerals that may not be immediately obvious to the geologists’ eyes. Olympus portable XRF (pXRF) analyzers are used for quick, reliable analyses at a fine scale to detect cobalt even in common minerals. This case study shows the pXRF results of samples provided by Electra Battery Materials Corporation (Electra), formerly known as First Cobalt.

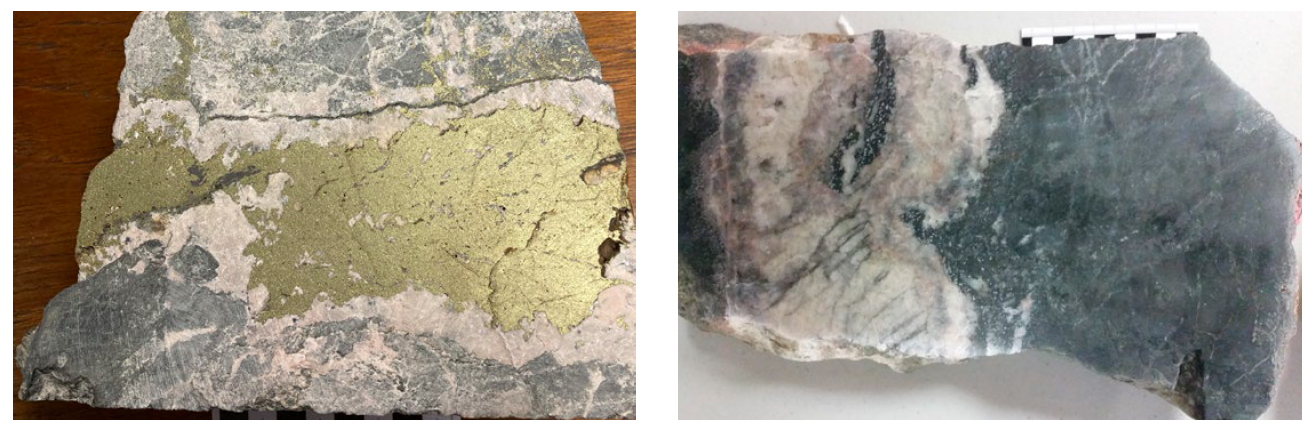

Figure 1. The occurrence of cobalt from Electra Battery Materials Corporation projects in the United States and Canada. A) Massive pyrite with fine and coarse grain sizes. B) Scanning electron microprobe image from the same sample showing cobalt within the pyrite grains. C) Colloform textured cobalt minerals within veins. D) Scanning electron microprobe image from the same sample showing skutterudite (cobalt arsenide mineral) and cobaltite (cobalt iron arsenic sulfide mineral).

Cobalt Exploration Campaigns Using pXRF Analyzers

To provide battery-grade nickel and cobalt, recycled battery, and precursor materials to North American supply chains, Electra is expanding a permitted hydrometallurgical cobalt refinery north of Toronto, Canada, and has exploration projects in this region and in Idaho, USA.

Electra has been using the Olympus Vanta™ handheld XRF analyzer on exploration campaigns in Canada and the USA since 2017. The mineral exploration company uses this pXRF analyzer in three main ways:

- Mineral identification: chemistry results derived by the pXRF analyzer are used to correctly identify complex cobalt mineralogy of rock and core samples; this data helps calibrate the geologists’ visual assessment

- Analysis of soil and stream sediment samples

- Estimating cobalt grade in rock and core samples to make real-time decisions during fieldwork programs

The Challenge of Analyzing Cobalt Using XRF

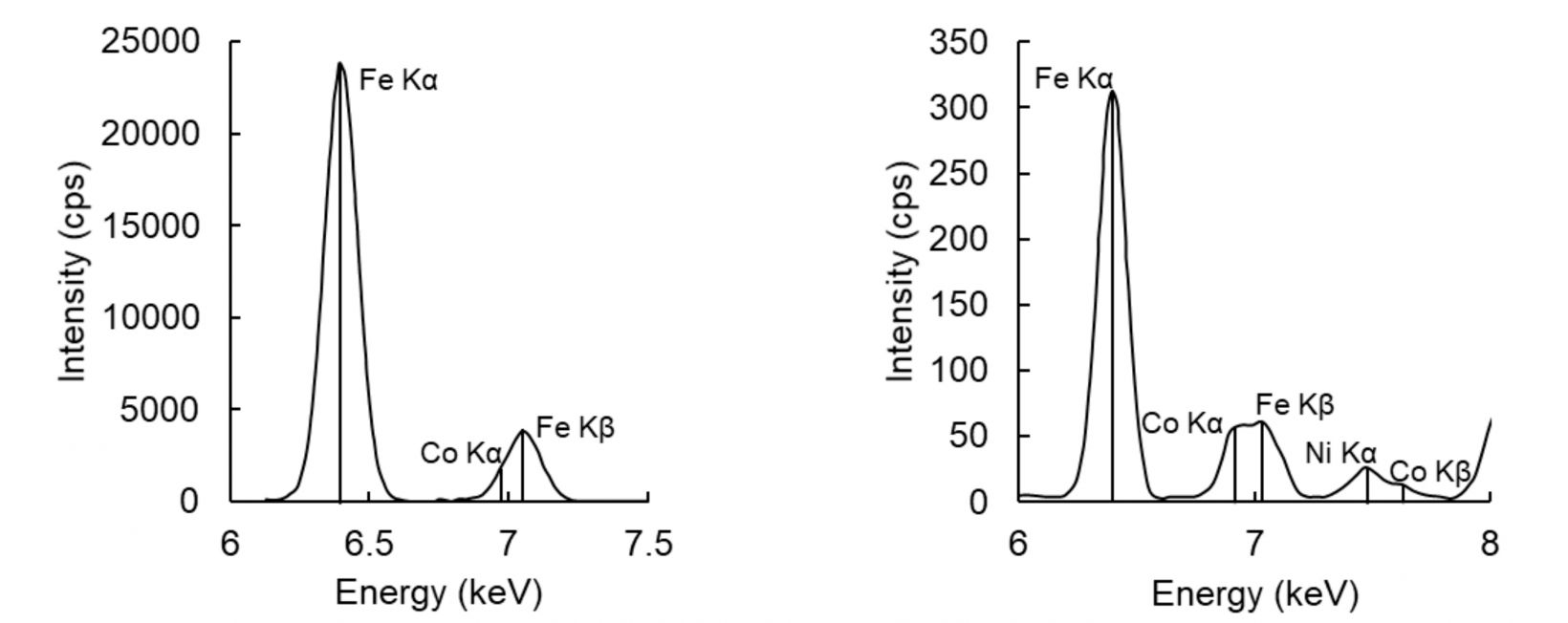

The XRF analytical technique is prone to interelement interferences. Iron (Fe) on cobalt (Co) and nickel (Ni) on Co are two common examples. This means that when a substantial amount of iron and nickel is present, it becomes difficult for XRF to identify cobalt at low levels. Unfortunately, these two elements are commonly associated with cobalt mineralization.

Figure 2. Traditional spectral overlaps of Fe and Ni on Co in cobalt-containing ores.

To solve this challenge, Olympus developed a GeoChem method for Vanta pXRF analyzers that offers improved analysis of cobalt in the presence of these other elements.

The method uses specifically developed deconvolution of the iron/cobalt/nickel peaks. Before deploying this solution, we tested it on several client samples in Australia to make sure that it produced good results. To review these test results, read our blog post on battery metal exploration and view our talk, Breakthrough Technology for Co Analysis Using Portable X-Ray Fluorescence.

pXRF Results from Cobalt Exploration Projects

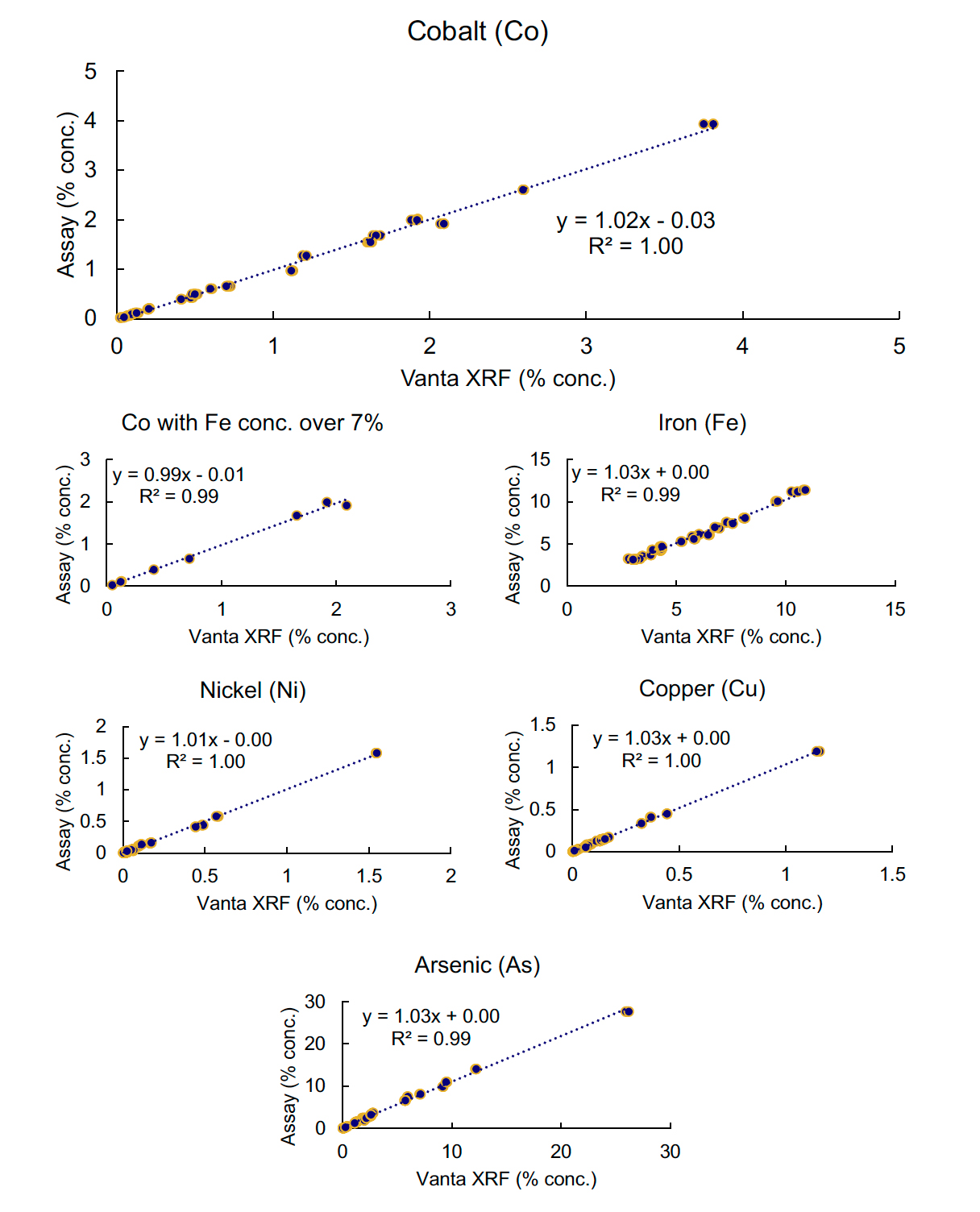

To further test and validate the Vanta analyzer’s cobalt-optimized GeoChem Method, Electra provided Olympus with 24 laboratory-assayed pulp samples from its Canadian exploration projects, encompassing various mineralization styles (pyrite, cobaltite, and skutterudite). Samples were placed in sample cups and tested under optimal conditions in a Vanta Work Station for 60 seconds per beam.

Figure 3. Vanta pXRF results vs. laboratory results from Electra’s Canadian exploration projects

Data derived from the Vanta XRF analyzer showed outstanding correlation with laboratory data for Co, even at concentrations below 0.05% and in the presence of iron (Fe) above 10%. Arsenic (As), nickel (Ni), and copper (Cu) data also demonstrated excellent accuracy compared with lab values.

Analysis of nonhomogenous rock, core, and soil samples is unlikely to provide equivalent levels of accuracy; however, much published work demonstrates the significant value of semiquantitative data to the mineral explorer. This can be evidenced by Electra’s continued use of the Vanta pXRF analyzer on nonhomogenous sample types and intention to use it as a vital tool in their workflows.

For more information on Vanta pXRF analyzers, reach out to us online or contact your local Olympus representative.

Olympus is dedicated to making people’s lives healthier and safer. We are committed to responsibly doing business and serving our markets in alignment with the Guiding Principles on Business and Human Rights set forth by the United Nations.