FOX-IQ Automated, On-line XRFFocus Tube and pipe manufactures use many different metals and alloys in their production lines. To avoid material mix-ups and to meet their customers' requirements, they must compare their product against acceptable alloy specifications. Particularly in the aerospace, petroleum and nuclear industries, the consequences of processing or fabricating with the wrong alloy material can be serious, resulting in product failure and eventual loss of business. High volume manufacturers need a fast, non-destructive method that offers 100% PMI (Positive Material Identification). |  |

We have designed the FOX-IQ Factory Online XRF system to perform automated on-line analysis for 100% high-volume process control. X-ray Fluorescence (XRF) is a proven analytical technique commonly used to quickly and non-destructively verify alloy grade and chemistry. Each FOX-IQ delivers fast, accurate grade ID, pass/fail tests and chemistry with automated links to the QC/QA reporting system. The system is set up for simple integration with existing or new PLC-controlled processes, or flexible enough to work with complicated user-designed programs.

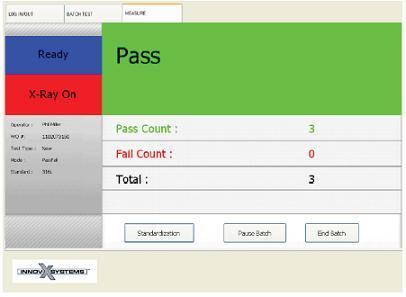

The FOX-IQ is controlled by an industry-hardened PC for start/stop, data acquisition, decision making and communication to external devices. FOX-IQ's powerful, yet user friendly software is customized for the tube/pipe industry and features automated retesting, multi-level access and an intuitive touchscreen interface. This CE certified system is engineered for 24/7operation in industrial environments; its compact design will fit in virtually all existing operations.

| FOX-IQ Modes of Operation The system comes with a standard reference library of common alloy fingerprints, though adding your own (up to 300 more) is a simple one minute procedure. Furthermore, once the unit has been taught a fingerprint, it will not need periodic recalibration. |

Analytical mode utilizes a Fundamental Parameters (FP) algorithm to determine elemental chemistry. The FP method utilized in Analytical mode is ideal for applications that require analysis of proprietary or uncommon alloys, for monitoring chemistry of tramp elements, or for monitoring chemistry during processing. The Analytical mode can identify an unknown material in approximately 5 seconds, with increased precision for longer test times.

FOX-IQ Performance

Experimental Application Results - 316/316Ti Processing Line

| Identification | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Chemistry | |||||||

| Sample | Ti | Cr | Mn | Ni | Cu | Mo | |

| 316 Ti a | 0.37 | 17.15 | 1.39 | 13.00 | 0.31 | 1.91 | |

| 316 Ti a | 0.32 | 17.12 | 1.32 | 12.71 | 0.44 | 2.03 | |

| 316 Ti a | 0.32 | 17.33 | 1.23 | 12.89 | 0.42 | 1.93 | |

| 316 Ti a | 0.46 | 17.21 | 1.29 | 12.52 | 0.37 | 2.04 | |

| 316 Ti a | 0.31 | 17.22 | 1.08 | 12.75 | 0.52 | 1.96 | |

| AVE | 316 Ti a | 0.36 | 17.21 | 1.26 | 12.77 | 0.41 | 1.97 |

| STD | 0.06 | 0.08 | 0.12 | 0.18 | 0.08 | 0.06 | |

| Sample | Ti | Cr | Mn | Ni | Cu | Mo | |

| 316 L a | ND | 17.67 | 1.53 | 13.81 | 0.47 | 2.47 | |

| 316 L a | ND | 17.98 | 1.67 | 13.74 | 0.54 | 2.55 | |

| 316 L a | ND | 17.76 | 1.57 | 13.74 | 0.57 | 2.46 | |

| 316 L a | ND | 17.68 | 1.59 | 14.04 | 0.48 | 2.47 | |

| 316 L a | ND | 17.88 | 1.69 | 13.68 | 0.51 | 2.62 | |

| AVE | 316 L a | ND | 17.79 | 1.61 | 13.80 | 0.51 | 2.51 |

| STD | 0.13 | 0.07 | 0.14 | 0.04 | 0.07 | ||

|

Takeaway - able to repeatably and reliably detect 0.35% Ti in only 4 seconds

Very quick, repeatable chemistry in 4 seconds of testing time | |||||||

| Distance | ||||||

|

Distance

mm | Ti | Cr | Mn | Ni | Cu | Mo |

| 0 | 0.32 | 17.26 | 1.19 | 12.98 | 0.37 | 1.95 |

| 2.5 | 0.32 | 17.09 | 1.27 | 12.95 | 0.36 | 1.99 |

| 4 | 0.32 | 17.04 | 1.36 | 13.11 | 0.40 | 2.00 |

|

Average of 10-3 second tests at different distances.

Concentration in %. The analyzer uses a normalization process that makes it much less sensistive to small changes to difference. (~1-2 cm) This will save you the headache of building complicated and expensive moving mount tables. | ||||||

Conclusion

The FOX-IQ Tube and Rod On-line Process Analyzer proved very capable of accurately analyzing samples in Pass/Fail and Analytical Modes. With accurate results within 5 seconds or less, the FOX-IQ will make a significant impact on tube and pipe manufacture in a high volume production line by providing quick, reliable, non-destructive alloy analysis.