Olympus portable XRF analyzers provide a rapid, nondestructive method for accurately determining the thickness of non-chromate conversion coatings. These measurements must fall within a target thickness range to ensure that subsequent paint coatings adhere properly and that the component is protected against corrosion.

Non-Chromate Conversion Coatings

Aluminum alloys are used for a range of commercial and residential construction materials. After the alloy is extruded, a conversion coating is applied to protect it against corrosion and ensure the proper adhesion of subsequent paint coatings.

Chromite conversion coatings have historically been popular, but hexavalent chromium poses environmental and health risks. Consequently, the European Union banned the coatings, leading to the rise of non-chromate conversion coatings as an alternative. Even in countries where hexavalent chromium is still allowed, many architects will only purchase material coated with non-chromate conversion coatings since they are safer and more environmentally friendly.

Titanium-zirconium (Ti-Zr) conversion coatings are popular non-chrome alternatives. Although they are safer, they are also colorless, making it impossible for an operator to visually determine if the coating has been applied evenly and in the right thickness. If the coating is too thick, there is the potential for adhesion failure while, if the coating is too thin, the aluminum alloy is more likely to corrode.

Vanta Portable XRF Analyzers

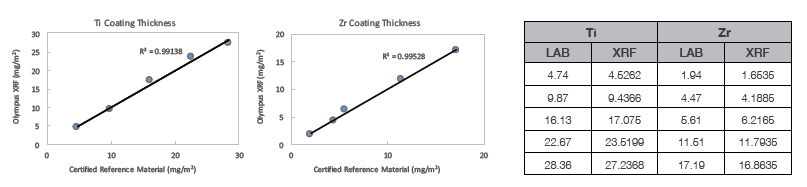

Vanta portable XRF analyzers provide a rapid, nondestructive method to ensure Ti-Zr-based conversion coatings have been applied and that the coatings are within the required thickness range. Data provided in Figure 1 illustrates the accurate coating thickness capabilities of the Vanta portable XRF.

Figure 1. Excellent correlation between results obtained using an Olympus Vanta XRF analyzer and coating thickness reference materials.

Benefits of Vanta™ XRF AnalyzersThe Olympus Vanta XRF instrument enables operators to analyze a range of coated materials in the warehouse or yard quickly and nondestructively. Features include:

*Requires optional wireless dongle. |  |