Benefits of Vanta™ XRF AnalyzersWhen accuracy and confidence count, the Olympus Vanta XRF instrument provides immediate, on-site elemental measurements for analyzing precious metals, including gold, platinum, silver, and rhodium. Features include:

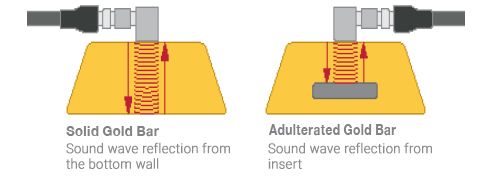

*1 With optional fan. | Olympus portable X-ray fluorescence (XRF) analyzers provide users with accurate surface chemistry of bullion bars, while Olympus ultrasonic flaw detectors provide a nondestructive, fast, and reliable method for helping ensure that gold bars have not been adulterated. Combined, these two technologies enable users to be confident in the purity and integrity of their bullion bars.Analysis without the need for drilling or cuttingThe rise in fraudulently adulterated gold bullion bars by inserting slugs of inexpensive metals (such as tungsten) is a concern for gold markets. These insertions are difficult, and often impossible, to identify visually, by measuring the weight, or using radiography technologies. Portable XRF analyzers provide accurate analysis of precious metals, but are limited to the surface of the metal that is being analyzed. Ultrasonic flaw detectors can be used to ensure that a bullion bar is homogeneous and free of insertions. When combined with portable XRF results, users can be confident that the surface chemistry obtained by their Vanta XRF analyzer is representative of the chemistry throughout the entire bar. Ultrasonic flaw detectors work by generating pulses of high-frequency sound waves in a material, which then reflect back to their source after they strike a boundary with a different material. This could be the bottom of the gold bar, an insertion within the gold bar (e.g. a tungsten metal insertion), or an internal void. Olympus flaw detectors can be used to distinguish between waves reflecting from the bottom of the gold bar and waves reflecting from insertions or internal voids.

This test is set up by coupling the transducer to a known good bar and identifying the echo from the bottom surface. A flaw gate may be used to monitor the interval ahead of this back wall. Any echoes appearing within the region marked by the gate indicate that the sound beam is reflecting off a discontinuity, and the bar should be further inspected by other means. |

Benefits of Vanta™ XRF Analyzers

When accuracy and confidence count, the Olympus Vanta XRF instrument provides immediate, on-site elemental measurements for analyzing precious metals, including gold, platinum, silver, and rhodium. Features include:

- Continuous operation at temperatures up to 50° C (122 °F).*1

- IP55/IP54 rated to withstand dirt, dust, and rain.

- Rugged and built to pass a 1.2 m (4 ft) drop test (MIL‑STD-810G) to help prevent breakages.

- Connect to the Olympus Scientific Cloud™ to access and share data across multiple platforms from any location.*2

*1 With optional fan.

*2 Requires optional wireless dongle.