Olympus portable X-ray diffraction (pXRD) and X-ray fluorescence (pXRF) analyzers provide technicians, engineers, and scientists with real-time, quantitative identification for a wide range of cement, concrete, and individual components. With onsite analysis, these compact instruments can identify and quantify the material phases quickly and accurately.

While sending samples to an outside lab can take days or weeks, cement analysis using Olympus’s patented pXRD and pXRF technology takes minutes or seconds. Using these instruments for cement production and quality control can help you identify the value of material feeds from quarries, stockpiles, and silos to the kilns and the mills using blending processes.

- Check calcium levels on the spot

- Know the quality of all the material you pull out of the ground

- Know the elemental composition of every pile in your storage yard

- Ensure you’re removing the right material from storage before it gets to the kiln

- Make sure you’re adding the right corrective materials

- Analyze feed stream materials

- Inspect incoming gypsum for the correct sulfate (SO4) content

- Test mixed material coming from the kiln to make your changeover faster

- Know the material chemistry of your mixed piles for reblending

- Do incoming QC on your kiln bricks to ensure they’re made of the correct materials to help avoid early failures

Benefits of Olympus XRD

Olympus pXRD technology has many benefits, including:

- Fast acquisition: go from sample prep to analysis in minutes

- Virtually maintenance-free: runs without the need for compressed gas, water cooling, a secondary chiller, or external transformer to decrease downtime and costs

- Easy sample prep: simple mortar and pestle process can be done by operators of all experience levels in the field quickly and without complex equipment

- Small sample holder: only requires 15 mg of material compared to the large batch required for conventional XRD

Quantification in the Field

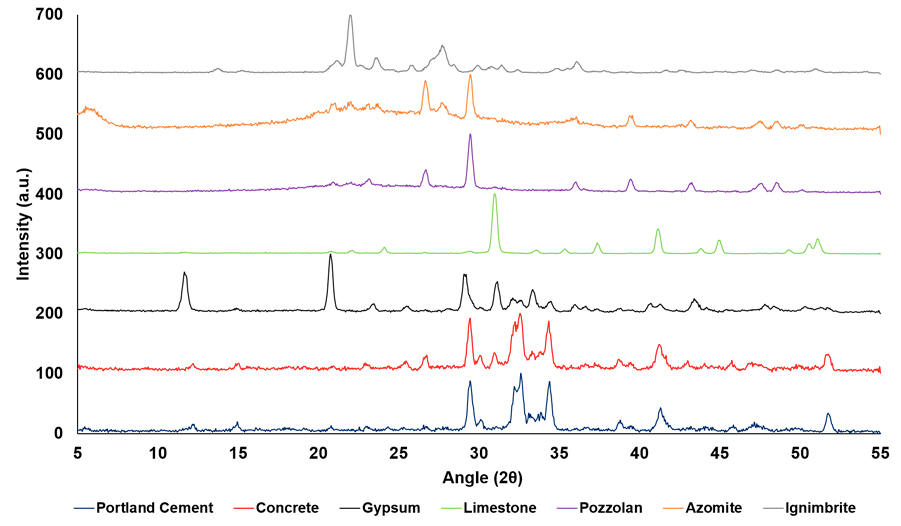

Olympus pXRD analyzers can identify all mineral phases in the field in real-time, regardless of chemistry and orientation. A variety of materials can be used with our Cu-tube X-ray diffraction analyzers, including Portland cement, concrete, gypsum, limestone, pozzolan, and more:

Olympus XRD analyzers can test a variety of materials for the cement production process.

Engineers can use this information on-site in real-time to better understand the chemical ratios and grades for cement, along with analysis of any additives used during the process. At the plant, engineers can obtain a chemistry or phase analysis on location and reduce the amount of out-of-spec clinker, raw material, and additives that need to be held and re-blended.

As shown in the diffractogram above, the Olympus TERRA™ II and BTX™ III XRD analyzers can quickly identify a variety of phases in the cement and aggregate industry. This includes calcium levels at the quarry, sulfate content for the gypsum feed stream, and any additives or imperfections that might be encountered along the way. Each component can be identified and quantified in real-time using Olympus’s innovative and integrated SwiftMin® automated phase ID and quantitative software, or with standalone software packages such as XPowder (included). These options make it even easier and faster to quantity the phase information and minerology during the entire process.

A technician quickly runs a test using the TERRA II portable XRD analyzer.

Additional Phase Identification

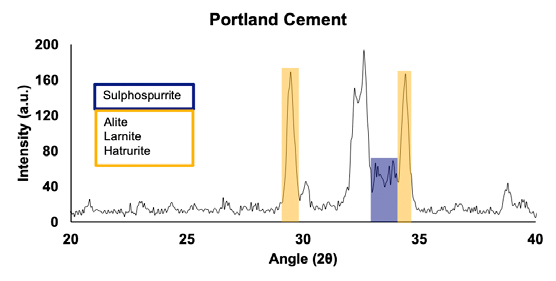

Concrete and cement are mostly composed of calcium silicates, sulfates, and carbonates, along with silica. While Olympus pXRD analyzers can easily and quickly quantify these components, they can also identify other phases in the product. These phases include sulphospurrite, also referred to as ternesite.

High levels of sulphospurrite lead to increased energy costs and decreased efficiency during production. Our TERRA II and BTX III pXRD analyzers can quickly and easily identify and quantify sulphospurrite, as shown below.

XRD analysis of Portland cement identifies and quantifies sulphospurrite.

In addition to the desired calcium silicate phases of alite, larnite, and hatrurite, there is a sizeable (20%) concentration of sulphospurrite contaminate in commercial-grade Portland cement. This, and similar intermediate phases such as alkali chlorides or alkali sulphates, will occur due to temperature differentials in the kiln or cyclone during production.

When these sulphospurrite rings are found in the fouling of kilns, they can cause various problems, such as damaging the kiln seal, increasing energy consumption, allowing more dust to get into the kiln, and decreasing safety. Over time, these fouled kilns may lead to an expensive unplanned downtime, so it is important to identify these potentially contaminate phases early.

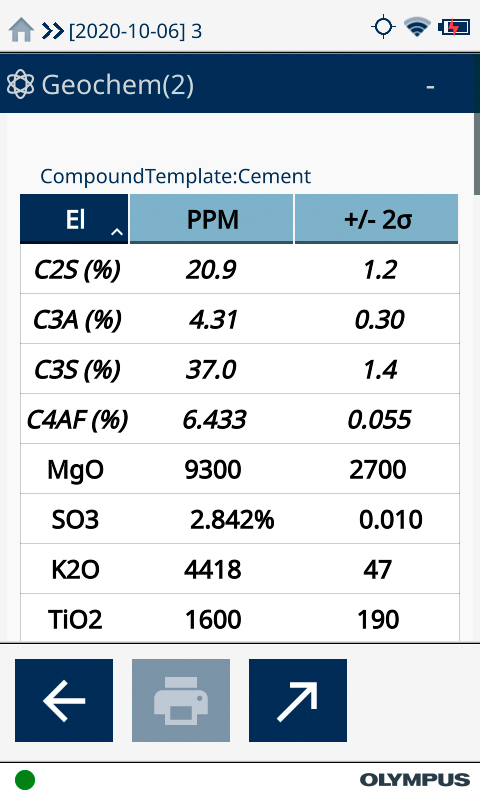

The Bogue Calculation

The Bogue calculation is used to estimate the four main minerals in the clinker quickly and easily in Portland cement: alite, belite, aluminate, and ferrite based on concentrations of various oxides, including silicon oxide, iron oxide, aluminum oxide, and calcium oxide. The Bogue calculation is shown below:

Alite (Ca3Si): C3S = 4.0719CaO - 7.6024SiO2 -1.4297Fe2O3-6.7187Al2O3

Belite(Ca2Si): C2S = 8.6024SiO2 + 1.0785Fe2O3 + 5.0683Al2O3 - 3.0710CaO

Aluminate (Ca3Al): C3A = 2.6504Al2O3 - 1.6920Fe2O3

Ferrite (Ca4AlFe): C4AF = 3.0432Fe2O3

Olympus Vanta™ portable XRF analyzers can quantify these compositions in 30 seconds or less of run time. Using the commercial Portland cement sample, you can calculate the unknown concentrations quickly and directly on the unit.

Vanta pXRF analyzers can help you easily test for critical components of clinker in cement in real-time without any external supplies, as shown above. Combined with the TERRA II or BTX III pXRD analyzers, these instruments provide you with a complete tool kit for concrete and cement analysis.

Cement analysis is quick and easy using a Vanta XRF analyzer.

Vanta XRF analyzers are rugged, reliable instruments for the cement manufacturing process.

Learn More about Portable XRF and XRD

Want to learn more about pXRF and pXRD in the cement production process? Reach out to your local sales representative to set up a demo or check out the following resources:

- Video: Handheld XRF for Material Quality Control in Cement Manufacturing

- Cement Industry Infographic

- AZoM Interview: How Can Handheld XRF Improve Cement Production Processes?

- International Cement Review: XRF and XRD Analysis to Hand

Olympus, the Olympus logo, Vanta, BTX, and TERRA are trademarks of Olympus Corporation or its subsidiaries.

SwiftMin is a registered trademark of the MinEx CRC.