Military forces around the world are extending the life of aging aircraft by using phased array ultrasound testing to detect cracks and other flaws to help prevent catastrophic failures. One time-consuming challenge is inspecting aircraft fastener holes to detect faying (back wall) surface cracks. |

Minimizing Aircraft DowntimeReducing the downtime associated with inspecting aircraft is critical. Current inspection methods require a lengthy mechanical breakdown to allow inspectors access to all the critical fastener holes. During this time-consuming process, hundreds of overhead fasteners must be inspected. |  The inspection area showing hundreds of overhead fasteners |

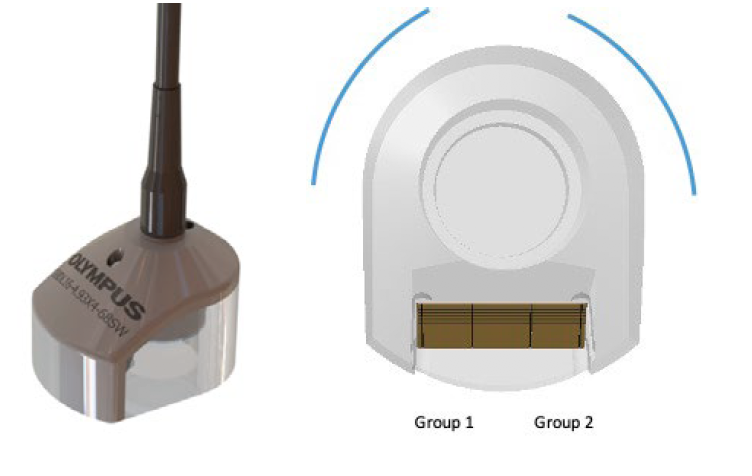

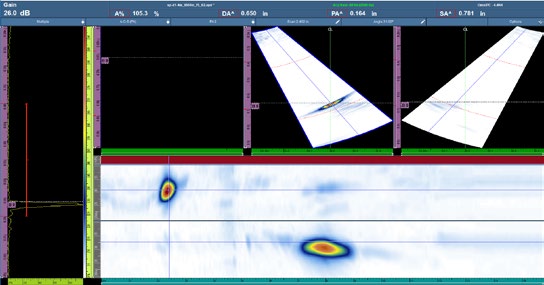

ConclusionThe Olympus small-access spinner probe improves coupling, detection, inspection time, and provides easy-to-interpret phased array ultrasound data. Please contact SCE.PM@olympus-ossa.com if you would like more information about this application, support for solving your own application, or need customized ultrasound transducers. |

Images supplied by the US Naval F-5 Adversary Program. |