Role of Portable X-Ray Fluorescence (pXRF) Spectrometry in Phosphate Investigations

Over the last decade, portable X-ray fluorescence (pXRF) spectrometry has shown to be a viable method for in-field geochemical analysis in phosphate investigations conducted by the mining and exploration industries. The Olympus Vanta™ pXRF spectrometer plays a critical role in this application by providing real-time quantification and analysis of phosphates. This application note demonstrates how the Vanta pXRF analyzer can accurately measure important phosphate minerals and other elements used in phosphate exploration.

Phosphate Rock Elemental Analysis

Phosphate is generally found in these five types of natural deposits: marine sediments, volcanic, metamorphic, eroded soil, and biogenic ores.1Phosphorite, broadly known as rock phosphate or phosphate rock, contains between 2% and 10% phosphorous by weight, or between 4% and 20% P2O5. As high-vitality phosphate mines are continually exhausted, there has been a steady trend of declining availability of high-grade phosphate sources.2> This decline has increased the need for precise and accurate readings of phosphate rock across all concentration levels and many elements.

Vanta™ pXRF analyzers can detect most elements from magnesium (Mg) through uranium (U) down to low single-digit parts per million (ppm) in most cases. While Vanta pXRF can certainly detect phosphorous (P), other detectable elements are critical to phosphate mining. Elements such as vanadium (V), nickel (Ni), molybdenum (Mo), silver (Ag), lead (Pb), thorium (Th), and uranium (U) are known as pathfinders, which are elements that can be used to find high-fidelity regions of mines.

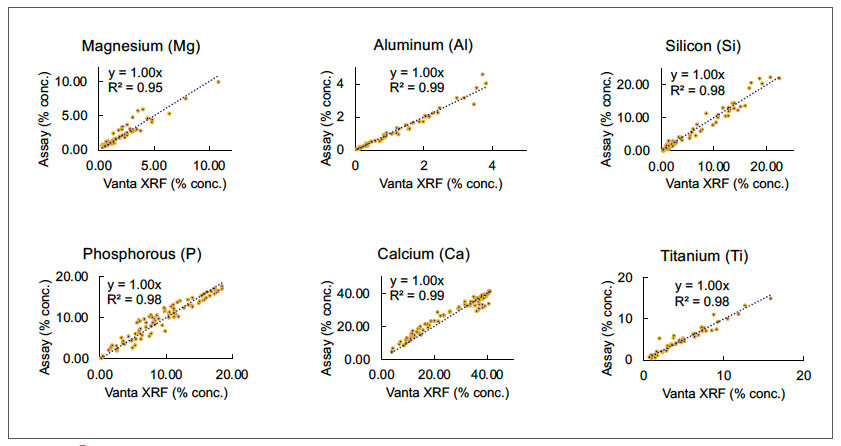

Determining the concentration of not only phosphorous, but also other lighter elements, such as magnesium (Mg), aluminum (Al), silicon (Si), calcium (Ca), and titanium (Ti) is crucial to a high efficacy tool. In a matter of seconds, the Vanta analyzer can provide accurate in-field concentrations of these elements and others with minimal sample preparation. This ability is very useful for making real-time decisions at a worksite, eliminating the expensive downtime involved in sending samples to an external lab.

Figure 1. Vanta™ pXRF performance of elements in phosphate rock samples compared to assay values using various samples supplied by customers

The data above illustrate the out-of-box performance of a Vanta pXRF analyzer on a range of reference materials made from real samples taken by customers. The high correlation between the reference data and the Vanta pXRF results shows that the Vanta analyzer provides excellent data quality on prepared samples from a variety of phosphate rock samples. The test times for these samples averaged less than a minute, with minimal sample preparation. Preparing the samples involved quickly hand crushing or grinding the sample down to particle sizes of less than 0.2 mm and collecting the particles into standard sample cups.

Phosphate Mineralization

Much of the phosphate mined today comes from sedimentary apatite. The general chemical formula for apatite is Ca10(PO4)6(OH,F,Cl)2, which is referred to as collophane in phosphate rock. The apatite-containing phosphorous deposits with high economic value can contain upwards of 20% P2O5 and over 35% CaCO3, along with some trace amounts of other oxides, such as magnesium and aluminum oxide.

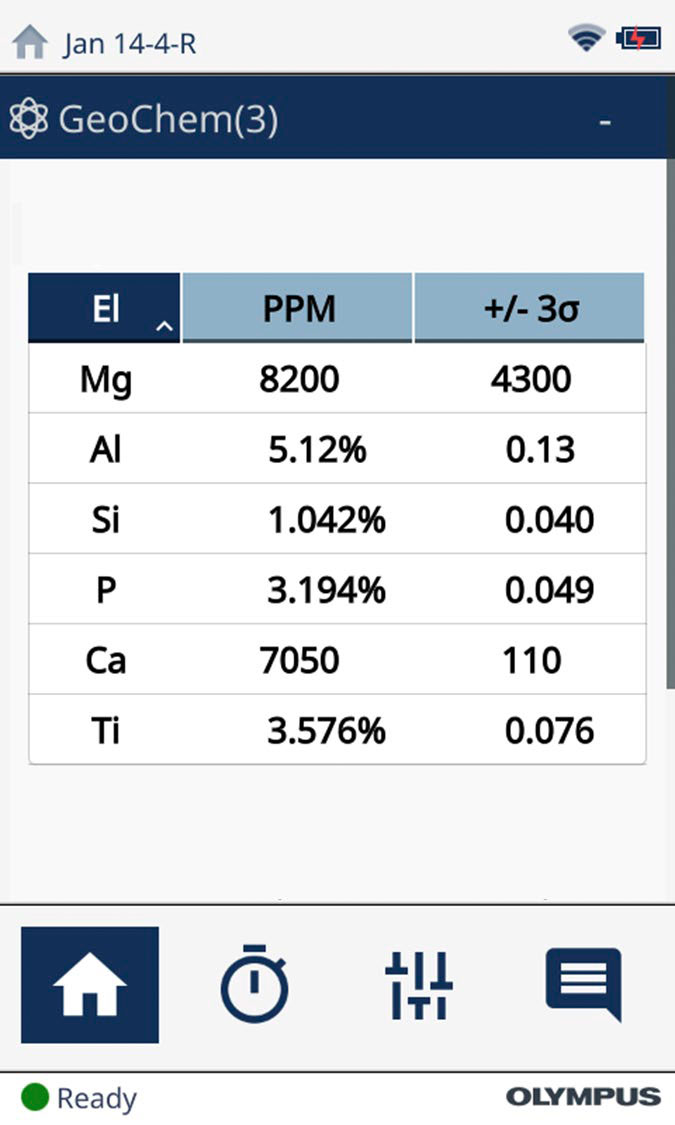

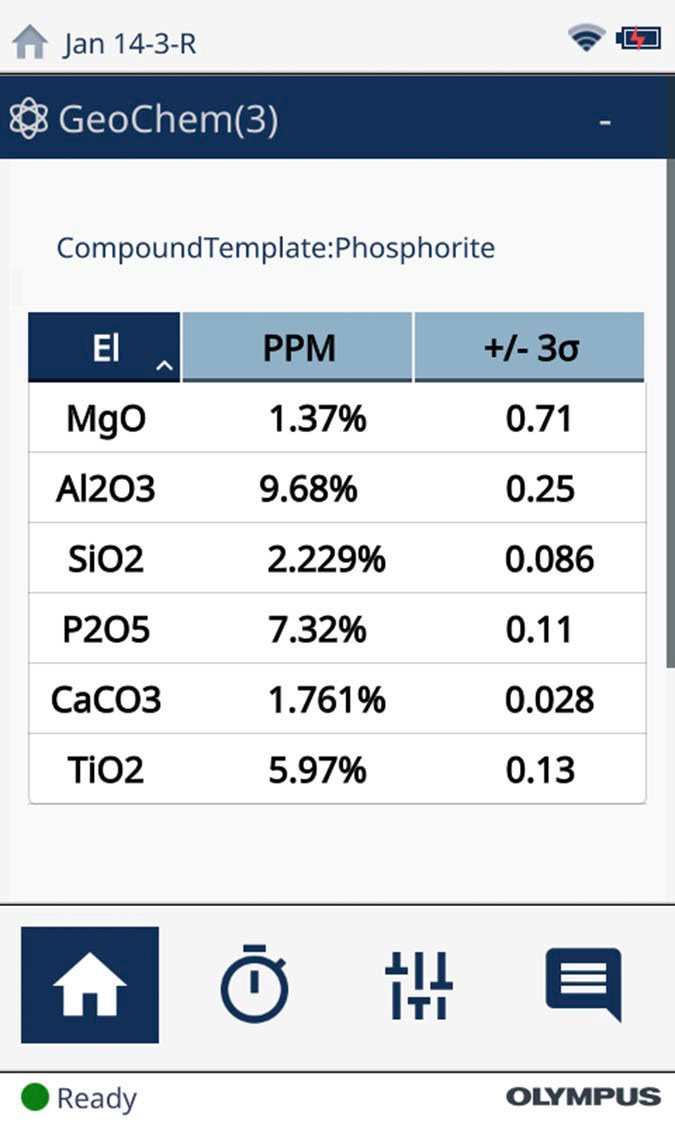

While calculating the elemental concentrations, the Olympus Vanta pXRF can also calculate these mineral and compound concentrations in real-time. Through the analyzer’s easy-to-use user interface, the user can set the spectrometer to report the calculated concentrations as compounds, as demonstrated in Figure 2. The Vanta™ analyzer’s software performs this calculation for the user, and it only takes a few seconds to switch between elemental and compound reporting.

Figure 2. Scan of a phosphate-rock-containing certified reference material (CRM) both without (left) and with (right) the Vanta analyzer’s Compound function enabled

It is estimated that over 75 million tons of mineable phosphate rock currently exists in the three largest phosphate-producing countries in the world—China, the United States, and Morocco—and a total of over 200 million tons is mined yearly worldwide.3, 4 The potential economic value of these phosphate deposits is enormous and therefore of great interest to those in the mineral mining and exploration industries. While mined phosphate is used in many industries, including detergents, animal feed, and industrial chemicals, over 90% of phosphates are used in nitrogen-phosphorous-potassium (NPK) fertilizers.4 The estimated value of this yet exploited phosphate, once mined, is over $2.2 billion USD.

Phosphate Rock Byproducts

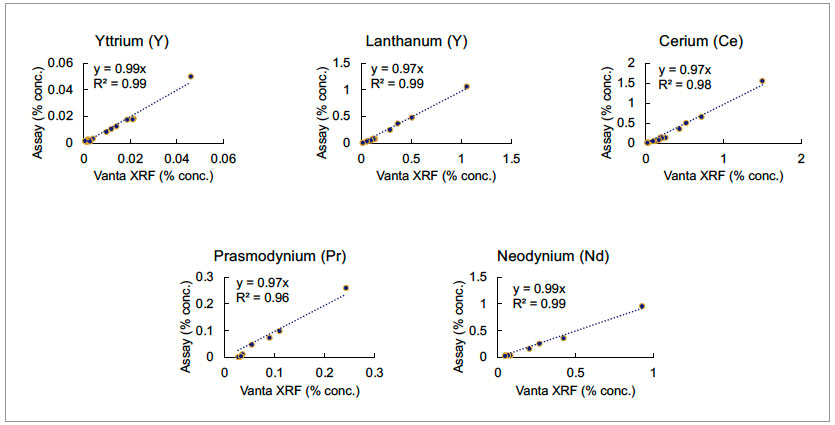

Many of these phosphate rock minerals contain viable amounts of high value materials, such as rare-earth elements (REEs) and uranium (U). As demand for these materials increases globally, the ability to analyze trace concentrations of these elements is economically important. Yields of these materials are higher in modern phosphate rock deposits than in existing mines and deposits.5 In addition to high performance on lighter elements and oxides, the Vanta™ analyzer can accurately and precisely calculate these heavier, higher cost elements.6

The graphs below illustrate the out-of-the-box performance of the Vanta pXRF on phosphate rock-containing certified reference materials (CRMs) supplied by Ore Research and Exploration Assay Standards (OREAS) with useable levels of REEs. High accuracy and precision between the CRM data and the calculated concentrations from the pXRF analyzer demonstrate the Vanta analyzer’s ability to provide rapid, high-quality data on economically valuable material in phosphate rock.

Figure 3. Vanta pXRF performance of rare-earth elements (REEs) compared to standards using samples provided by OREAS

Analytical Advantages of Olympus’ Vanta™ pXRF Analyzer

The Olympus Vanta pXRF offers numerous analytical advantages over other XRF testing techniques and testing methods. The main advantages are:

- Minimal and inexpensive sample preparation

- No need for extra hardware or testing requirements, such as sample chambers, external power, or compressed gas

- Rapid and high-throughput testing, producing accurate results with high precision in seconds

- Onsite scans without the need for expensive laboratory tests or downtime at the worksite

Learn more about the Vanta portable XRF analyzer on our website or reach out to your local sales representative to set up a demonstration.

References

- Hasikova, J., Sokolov, A., Titov, V. and Dirba, A., 2014. On-line XRF analysis of phosphate materials at various stages of processing. Procedia Engineering, 83, pp.455-461.

- Lemiere, B., 2018. A review of pXRF (field portable X-ray fluorescence) applications for applied geochemistry. Journal of Geochemical Exploration, 188, pp.350-363.

- Britt, Allison. "Phosphate." AIMR Report 2013 (Report). p. 90.

- Stephen M. Jasinski, "Phosphate Rock". US Geological Survey, Minerals Yearbook, 2013

- Emsbo, P., McLaughlin, P.I., Breit, G.N., du Bray, E.A. and Koenig, A.E., 2015. Rare earth elements in sedimentary phosphate deposits: solution to the global REE crisis?. Gondwana Research, 27(2), pp.776-785.

- Litofsky, J. Portable XRF for Rare-Earth Element Identification and Exploration [White paper]. 2020. Olympus Corporation of the Americas.