Background

Worldwide power generation amount has been increasing every year. In addition to thermal, hydraulic and nuclear power plants, use of natural energy, such as wind, solar, ground heat and wave, has become more popular in recent years. However, power generation by natural energy such as wind is contingent on the changing natural environment and only provides irregular generation capacity; thus its use is limited to supplementary power generation.

Because electricity is unfitted for storing, excessive power generation only results in waste. On the other hand, when power generation capacity is not enough, an electricity shortage may cause power outages, which can cause the market to panic. To correspond to fluctuating electric power demand, stable supply supported by flexible generation is essential.

Hydraulic power generation is flexible power generation. Electricity companies combine hydraulic power plants and other power plants to keep electricity supply at the optimal level. Particularly, during peak period in the summer, when electricity demand extremely increases, hydraulic power generation is an effective power generation method.

Feature of Hydraulic Power Generation

Hydraulic power generation can accommodate fluctuating electricity demand effectively. This feature comes from the generation process of hydraulic plants. Unlike power generation by combustion turbine system, hydraulic power generation uses the energy of a water stream. Thus, it enables effective control of generation capacity by only regulating the flow rate of water. In addition to this feature, hydraulic generation also has advantages such as high generation efficiency with low carbon dioxide emission.

Hydraulic energy is generated by water flow and is maximized when water falls freely, such as in dams. While other power plants, such as thermal power plants, are concentrated close to shores because they use seawater for cooling of steam, hydraulic plants are located in mountainous regions to leverage height difference.

Scope of Inspection in Hydraulic Power Plants

In hydraulic power plants, the scope of regular inspections is different from other types of power plants. Typical inspection items are as listed below:

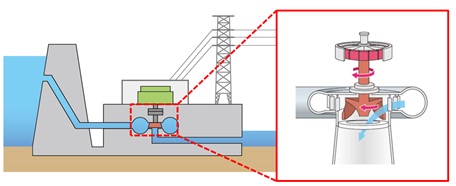

- Blades of water wheels (Fig. 1)

- Shafts and bearings of water wheels (Fig. 1)

- Deposition material within water piping and the like (earth and sand, wood, insects, etc.)

- Regulation valves for water flow

- Transformer

- Power transmission towers

Fig. 1 Magnified view of water wheel for power generation

Bigger blades of water wheels provide higher generation efficiency; thus, stable generation of great capacity is enabled. Shafts which support blades also grow larger in keeping with larger blades. The shaft bearings become larger as well. In dam lakes, earth and sand washed away from upper stream are deposited; thus, they are designed to have a large depth from the lake surface to the bottom. Compared with other power plants like thermal, hydraulic power plant facilities are enormous and require particularly longer RVI equipment. RVI equipment needs to not only to be large in length, but also have great articulation.

In most cases, hydraulic power plants are located in the mountains which results in long distance power transmission to destinations. Consequently, high voltage transmission at hundreds of thousands of kW is indispensable to reduce transmission loss which also requires huge power transmission towers to support heavy transmission lines. Maintenance control of these towers is also essential. Pillars of the huge power transmission towers have pipe structures to ensure strength. It is widely known that birds and small animals may build nests inside these pipe structures, causing corrosion. Videoscopes are used to check that.

Other Inspection Equipment

For inspection of hydraulic power plants, inspection equipment other than videoscopes is also used.

- X-Ray Fluorescence Analyzer

X-Ray fluorescence analyzers are used to analyze worn metal parts installed in areas subject to wear, such as bearing and cause lubricant leakage.

Such inspections are regularly conducted to secure safe operation management of facilities. Hydraulic power plants have an estimate life of 100 years. They are used for more than twice as long as other types of power plants; hence regular inspections are even more significant.