In power generation process piping, carbon steels containing low amounts of chromium (Cr) are susceptible to accelerated corrosion. Monitoring chromium content with Vanta handheld XRF analyzers is crucial to predicting useful pipe life.

| Carbon steel process lines can form a native protective oxide (magnetite or hematite) on the surface of the piping. At a high flow rate, this oxide coating may be removed. As the piping material attempts to regenerate the native oxide layer, the regenerated coating is also removed because of the high flow rate. This corrosion phenomenon is called flow accelerated corrosion (FAC). FAC is often made worse with turbulent flow from fittings such as elbows, tees, and reducing couplings. Corrosion models predict carbon steels containing less than 0.04% Cr are susceptible to FAC. This monitoring threshold is within the analysis range for chromium in iron-based steels with Olympus Vanta instruments. Small increases in the amounts of Cr in carbon steel piping will significantly reduce the rate of flow accelerated corrosion. Consequently, highly accurate measurements of low levels of Cr in carbon steel are critical for predicting the end of life in these pipes. |

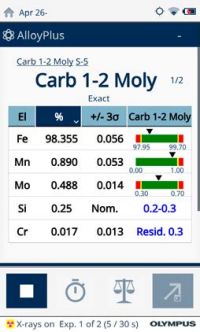

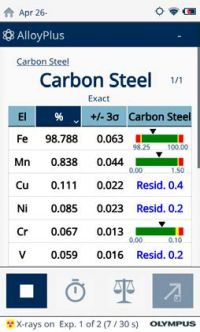

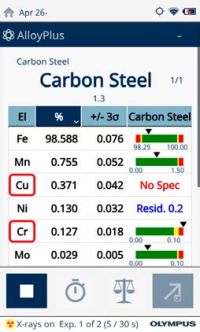

Below are on-screen results of a Vanta analyzer (Model VMR) during Cr analysis in carbon steels. Accurate Cr readings at levels needed for FAC prediction, as shown here, are generated in less than seven seconds.

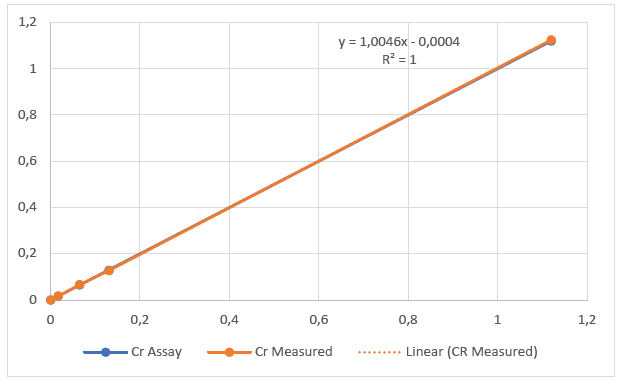

Sample being tested: IARM 229B Cr assay value: 0.017% | Sample being tested: IARM 209A Cr assay value: 0.065% | Sample being tested: IARM 28B Cr assay value: 0.13% | Sample being tested: IARM 35B Cr assay value: 1.12% |

Chromium Performance in Carbon Steels

| Vanta handheld XRF can quickly and accurately measure low levels of chromium in carbon steels to determine piping’s susceptibility to flow accelerated corrosion. Knowledge of chromium content allows a power generation plant to schedule piping repairs appropriately and proactively to minimize the risk of leaks or failed fittings. |