두께 및 결함 검사 솔루션

고급 NDT솔루션

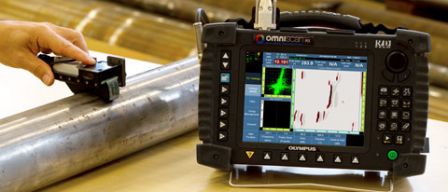

Olympus has an extensive portfolio of inspection solutions that offer unmatched capability for applications ranging from weld inspections to the detection of hidden cracks, voids, porosity and other internal irregularities in metals, composites, plastics and ceramics. Our high quality inspection solutions offer numerous practical measurement features, application-specific software, ease-of-use, versatility, and ruggedness.

Weld Inspection Solutions

Our full range of weld inspection solutions provides unmatched capabilities for applications that include the location and sizing of hidden cracks, voids, disbonds, and similar discontinuities in welds, forgings, turbines, and other structural components. We offer a wide range of measurement features and application-specific software options.

Corrosion Inspection Solutions

Olympus has a wide range of innovative products utilizing advanced technologies for the manual or automated inspections of internally corroded pipes and tanks, high-temperature surfaces, corrosion mapping of large pressurized vessels and stress corrosion cracking are typical applications that require either manual or automated inspections.

Guided Wave Solutions

The UltraWave LRT is a turnkey solution that uses guided wave technology and excites low-frequency ultrasonic waves that propagate in the axial direction of pipes, from both sides of the probe collar.

Composite Inspection Solutions

Olympus offers complete solutions for the inspection of carbon fiber reinforced polymers flat panels and radii. These solutions are based on the field-proven OmniScan® PA flaw detector, the GLIDER™ scanner (flat panels), and phased array probes dedicated to CFRP inspections.

Tube Inspection Solutions

Tube inspection solutions are based on the MultiScan MS5800 multitechnology instrument. This instrument supports eddy current (EC), remote field testing (RFT), and magnetic flux leakage (MFL) inspection techniques. The MS5800 also supports the internal rotary inspection system (IRIS) ultrasound technique.

Industrial Scanners

Industrial XY (motorized and manual) and manual weld inspection scanners provide reliable, accurate performance in a wide range of heavy duty industrial applications in which scanners are used to improve quality and reduce costs. PA scanners and scanner accessories such as motor controllers and water pumps complete the Olympus line of scanner products.

Aerospace Inspection Solutions

Olympus offers several aircraft maintenance solutions based on both phased array and eddy current array technologies in connection with the OmniScan instrument. Surface and subsurface aluminum fuselage can be easily inspected. Ideal for enhanced speed, detection, and repeatability.

Stress Corrosion Cracking Solutions

Olympus offers a range of productive solutions to detect or evaluate the depth of surface-breaking stress corrosion cracking. These solutions are based on the OmniScan MX ECA, a powerful and easy to use eddy current array flaw detector.

Transportation Solutions

The Olympus FOCUS LT/TomoView package is used to build fully automated high-performance train wheel inspection systems designed to match freight and high-speed train wheel inspection requirements while minimizing cycle time.

Heavy Forging Solutions

For high-performance heavy forging Inspection, the FOCUS PX uses the latest Olympus phased array technology to generate unprecedented signal-to-noise ratio (SNR). Four additional dedicated conventional UT channels are available for added flexibility in heavy forging inspection configurations.죄송합니다. 이 페이지는 해당 국가에서 사용할 수 없습니다.

아래 양식을 작성하여 원하는 내용을 알려주십시오.