Fast Live Analytics and Review

|

The CIX100 system offers high-performance image acquisition and precise live analytics of both reflective and non-reflective particles ranging from 2.5 μm up to 42 mm in a single scan thanks to a patented* polarization method. This all-in-one-scan solution enables scans to be completed twice as fast as the classical method (Inspector series). Counted and sorted particles are displayed live and sorted into size classes while the scan is acquired, supporting direct decision making and helping ensure a fast reaction time in case of a failed test. All relevant data are displayed live on a single screen during the inspection, enabling the operator to stop or interrupt the inspection if a test fails. |

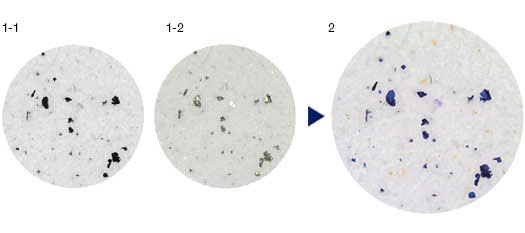

Capture Data in a Single Scan

An innovative polarization method based on wavelength separation and color detects both reflective (metallic) and non-reflective particles in a single scan. Integrated into the microscope frame, this high-throughput design enables scans to be completed twice as fast as the classical method (Inspector series) and eliminates moving components from the optical light path, such as the polarizer, which could negatively impact the system stability, leading to potentially incorrect results. This all-in-one-scan technique increases the number of inspected particles, reducing the cost per test and shortening the reaction time in case of a failed test.

1: Classical method, 2: Single-scan method

(1-1: First image of non-reflecting particles, 1-2: Second image of reflecting particles, 2: Single-scan solution: Combined)

An innovative polarization method detects both reflective (metallic) and non-reflective particles in a single scan.

Review Particles in Real Color

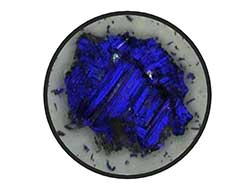

Activating real color mode enables users to view particles in their actual colors, providing additional information to identify the particle type as metallic or non-metallic.

The all-in-one scan shows all reflective particles as blue in polarization, indicating these particles are metallic. In real color mode, the blue color of reflective particles is omitted, and the true colors of all particles are shown in the brightfield image. Materials that are actually blue remain blue, while metals show their metallic shine and the reflections typical for the material.

With these helpful visuals, users can better understand the nature of each particle and quickly confirm the particle type.

| Particle as seen by the system during detection and analysis. The blue color indicates that this particle is metallic. |

| The same particle as seen during the review mode in real color using the U-ANT filter and the color correction mode. The particle is confirmed as metallic. |

Identify Filter Coverage

| The sample overview image is created at the beginning of the sample inspection and displays the entire filter at low magnification. The overview image helps to identify filter coverage or particle clusters before the sample inspection starts. If the filter assignment is higher than desired, the user is automatically informed and can react accordingly. |

Sample Information Overview

| Inspection configurations are used to specify all parameters for sample inspection. The sample information area lists the most important data. |

Live Analytics for Real-Time Results

| Contaminants are automatically analyzed and sorted into size class bins defined by the selected standard and are color coded to clearly indicate which size class exceeds a predefined limit. A statistical control chart function visually illustrates the level of particle class compliance, for improved reliability. Predefined acceptable particle counts per size classes are displayed, and the sample can be validated (OK) or rejected (NOK) even before the complete membrane is acquired. Required by electric mobility industries and medical device industries, CIX100 v. 1.6 software enables users to evaluate approval limits for individual particle types. An acoustic signal can be switched on when the approval reads NOK or the inspection is finished. |

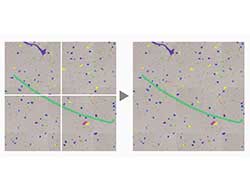

Detect Dark, Bright, Small, and Large Particles

| Live processing and classification of both small and large particles according to international standards (2.5 µm up to 42 mm). Image stitching automatically reconstructs images of large particles. Scan dark particles on a bright background or vice versa. |

Time Information

| Clearly view the time remaining for sample acquisition. |