Introduction

Olympus handheld X-ray Fluorescence (XRF) analyzers provide high-performance, real-time data for rapid elemental analysis of metallic samples such as Gold (Au) pin samples as well as mill feeds, precipitates, and environmental samples within gold mines.

The DELTA handheld XRF analyzer is used by laboratory personnel as a screening tool and in some cases as replacement for fire assay techniques. Advances in XRF detector technology and signal processing have improved the precision, the limits of detection, increased the number of elements that can be measured, and vastly reduced analysis test times.

These analyzers can provide a rapid return on investment in a gold mine site laboratory.

Benefits of Handheld XRF are:

- Analytical turnaround time reduced from several hours to several minutes

- Significant cost savings associated with reduction in lab technician time and reagents consumed

- Improved metallurgical recovery of Au in the mill by using handheld XRF for daily stockpile/feed analysis of Silica

- Laboratory safety, industrial hygiene and environmental performance improvements

Return on Investment

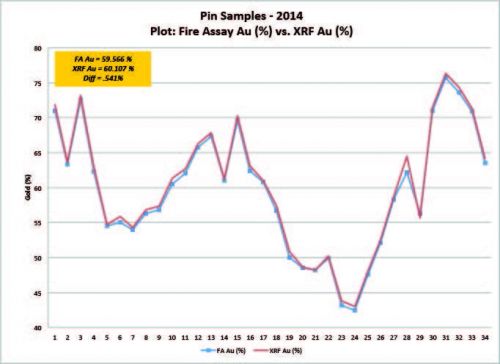

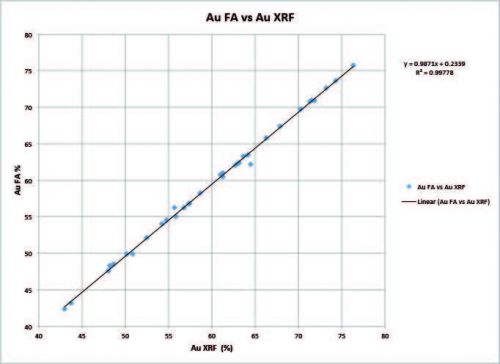

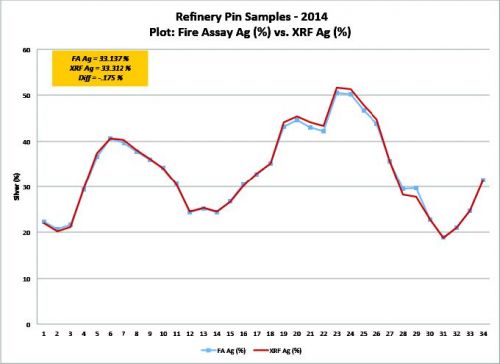

Olympus DELTA Handheld XRF analysis has been used as a screening tool and is now being used in some cases as a replacement technique for Gold (Au) and Silver (Ag) fire assays in gold mine laboratories. Linear regression analysis and other comparison studies (above), demonstrate outstanding agreement between XRF and fire assay techniques for the analysis of Au and Ag content within refinery pin samples. Cost savings are realized from reduced preparation and analytical time, labor cost reduction, and lack of reagent consumption when compared to fire assay analysis. Examples from one mine demonstrate preparation and analysis time can be reduced from 2 hours using traditional fire assay methods to 2 minutes using handheld XRF. Testing with the XRF simply involves rolling (flattening) the pin and performing multiple short tests (10 seconds in some cases) at different places on the pin and calculating the average.

Improvement in Laboratory Safety, Industrial Hygiene and Environmental Performance

1. Laboratory Safety

- Handheld XRF does not require the use of concentrated nitric and hydrochloric acids for sample prep, as required in the fire assay

- Handheld XRF does not expose the technician to potential skin burns and inhalation of lead fumes from the furnaces and the cupels, as can happen during the fire assay process

- Use of the handheld XRF affords less heat fatigue from reduced furnace usage and physical fatigue associated with twisting/ loading of furnaces

2. Industrial Hygiene

- Reduced exposure to Pb Oxide (used in fire assay process), which has a potential beneficial impact on technician blood lead levels

- Real-time monitoring of SiO2 dust levels in the mine and laboratory space – there is no need to wait for results from an offsite lab (turnaround times are often 2 weeks)

3. Environmental Performance

- Handheld XRF affords real-time analysis of environmental samples (e.g., SiO2 dust, soil contamination) rather than reliance on offsite laboratories

- Reduction in hazardous waste associated with the fire assay process

Mill Feeds, Precipitates, and Bullion Penalty Elements

- Excellent correlation demonstrated between handheld XRF and ICP for Silica

- Daily analysis of stockpile samples for silica using the XRF helps inform metallurgists about correlation between quartz content and potential lower Au recoveries associated with grinding effectiveness

- Use XRF to analyze refinery precipitate for Cu, Bi Se, Pb, Fe and SiO2

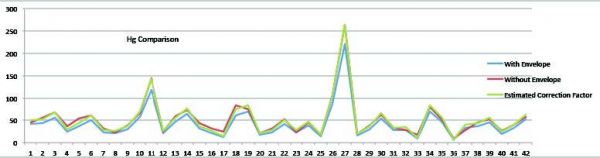

- Use XRF data on Pin samples to determine penalty elements in bars and flux adjustments in precipitates