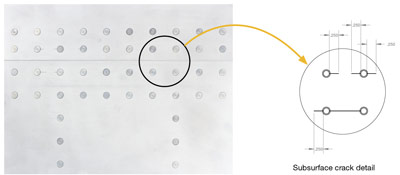

Commercial and military aircraft are built by joining overlapping aluminum sheets together with thousands of fasteners. Fatigue cracks on the underlying layers of aluminum are often concealed by the first sheet layer. To guarantee the integrity of any airplane, these hidden flaws must be detected and repaired during regular in-service inspections.

As a part of its series of aerospace solutions, Olympus proposes an innovative fastener and subsurface crack inspection technique, which propels eddy current technology into previously uncharted territory. This new technology provides an incredibly clear image of cracks under the first layer of aluminum aircraft skin, providing efficient and reliable results.

Features

- Replaces magneto-optical imaging (MOI).

- The 32-coil probe provides large coverage.

- Avoids paint removal; simplified process equals time-savings.

- With continuous mode, the scan imagery reveals inspection results without interruption.

- Data recording for professional reports.

- Probe positioning not as critical as a sliding probe.

- Optimized to detect typical subsurface cracks in aluminum sheets of commercial and military aircraft.

Subsurface Crack Area

| Conventional eddy current impedance plane with a 32-channel signal |  | Crack orientation on the right |

| Crack on both sides of the fastener | ||

| Zipper crack indication | ||

| Detailed subsurface crack ECA imagery | Crack orientation on the left | |

| Good fastener indication | ||