Introduction

The unobstructed and reliable flow of crude oil products is of critical importance to the industrialized world. Over time, obstructions in pipelines can build up and impede the free flow of crude oil. Olympus’ TERRA X-ray diffraction (XRD) analyzer is used to identify the scaling or corrosion that cause blockages so users can devise an appropriate treatment plan.

Identifying Corrosion

Corrosion in oil wells and pipelines is primarily found as ‘scaling,’ a build-up inside of pipes and valves, or as ‘rusting,’ a wearing away of the pipes and valves. Corrosive residue is analyzed to identify the specific phases/ compounds involved. Common phases/compounds of corrosion include magnetite, barite, calcium carbonate, and gypsum. All these compounds and more are quickly and easily identified using XRD.

Once the phase/compound of the corrosion is identified, the conditions that formed it can be determined, such as dissolved element mix, temperature, pH, presence of bacteria, and/or oxygenation. This information can then be used to determine how to remediate the corrosion and/or prevent further corrosion.

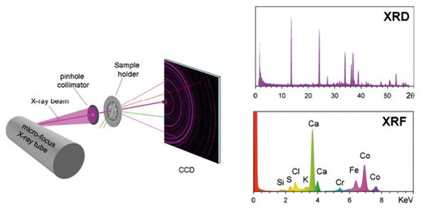

The portable Olympus TERRA XRD analyzer is built to be rugged, so users can take it into the field to identify the forms of corrosion taking place on-site. The TERRA incorporates patented technologies from NASA and Olympus to perform the XRD analysis. Its unique sample handling system collects structural (mineralogy/phase) and cursory elemental (chemistry) information. Operators utilize this information to help identify the sample with the aid of a dedicated application database.

The portable TERRA XRD analyzer can identify corrosive compounds/phases including those found on carbon steel piping, at oil wells, around municipal water, in offshore or Oceanside locations, and caused by sulfur reducing bacteria. The TERRA is simple to use for fast and accurate corrosive residue identification.

With the TERRATM, quickly identify:

- Carbon steel piping: Magnetite (Fe₃O₄), goethite (α-FeO(OH)), ferrihydrite (Fe₅O₇(OH)x4H₂O), lepidocrocite (γ-FeOOH), feroxyhyte (FeO(OH)), akaganeite (FeO(OH)), hematite (Fe₂O₃), and wüstite (FeO)

- Sulfur reducing bacteria (SRB): Pyrrhotite and pyrite

- Off shore/Oceanside: Akaganeite (FeO(OH))—especially in the presence of chlorides

- Oil well: Barium sulfate (barite), calcium carbonate (calcite), calcium sulfate (anhydrite, gypsum), strontium sulfate (celestite), iron oxides/carbonates/hydroxides, lead sulfi de, and zinc sulfide

- Municipal water: Quartz, albite, gypsum, chlorite, illite, actinolite, microcline, struvite, jarosite, iron precipitates, and carbonates

Corrosion Inspection Analysis with the Olympus TERRA XRD Analyzer

The Olympus TERRA XRD was used to analyze four samples of various pipeline corrosion materials. Sample preparation with the TERRA was easy. The samples arrived in powder form so they did not require any further preparation. Had any of these samples required crushing, the process would be easy using the fi eld preparation kit supplied with all Olympus XRD instruments (Figure 1). Each sample was sieved using 120–140 mesh and inserted into the TERRA’s patented sample chamber (Figure 2).

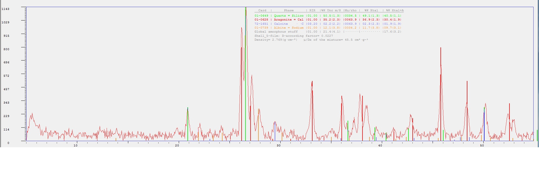

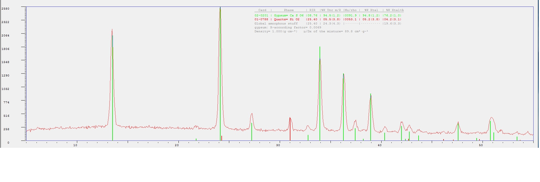

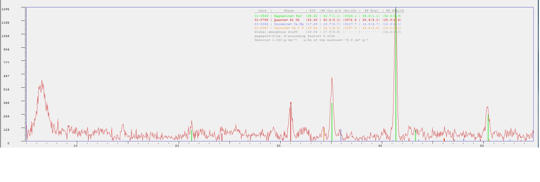

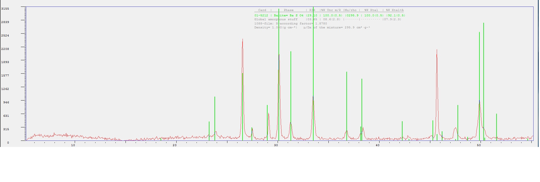

Each sample was analyzed for approximately 15 minutes and evaluated with XPowderTM, Olympus’ standard XRD analysis software. The relative intensity ratio method was used to quantify the identifi ed minerals. The results for all four samples are illustrated in Figure 3a-d. The graphs show the diff raction peaks for each sample. The Olympus TERRA Smart Sense output enables greater defi nition and clarity of peaks in contrast to the standard output. Smart Sense is a unique feature available on TERRA which optimizes peak-to-background performance. Since the sensor is both energy and position sensitive, Smart Sense can prevent photons that are not related to the XRD experiment from impinging on the sensor. As such, stray X-ray photons are eliminated from the analysis (Figure 4).

|  |  |  |  |

| Figure 1A | Figure 1B | Figure 1C | Figure 1D | Figure 2: The TERRA’s sample chamber. |

Figure 1: Elements of the sample preparation kit. 1A and 1B illustrate how samples are crushed in the fi eld. Use a mortar and pestle (1C) to reduce particle size. Sieve the powder (1D) to ensure uniform particle size.

TERRATM Sample Analysis Data

The analysis results for all four samples are presented below with the phase reference fi ngerprints overlaid on the graphic. Customized library searches can be made with TERRA sample data analysis.

Aragonite Calcite Albite Quartz

| Compound/Mineral | Spectral Marker Color | Result =% | Chemical Formula |

| Quartz | Green | 49.1 | SiO2 |

| Aragonite | Red | 36.9 | CaCO3 (Orthorhombic) |

| Calcite | Blue | 2.3 | CaCO3 (Trigonal) |

| Albite | Yellow | 11.7 | NaAlSi3O8 or Na1.0–0.9Ca0.0 |

Gypsum Quartz

| Compound/Mineral | Spectral Marker Color | Result =% | Chemical Formula |

| Quartz | Red | 5.2 | SiO2 |

| Gypsum | Green | 94.8 | CaSO4·2H2O |

Magnetite Quartz Calcite Dolomite

| Compound/Mineral | Spectral Marker Color | Result =% | Chemical Formula |

| Quartz | Red | 30.6 | SiO2 |

| Magnetite | Green | 38.2 | Fe23O4 |

| Calcite | Yellow | 16.6 | CaCO3 |

| Dolomite | Blue | 14.6 | CaMg(CO3)2 |

Barite

| Compound/Mineral | Spectral Marker Color | Result =% | Chemical Formula |

| Barite | Green | 100 | BaSO4 |

Conclusion

Corrosion residue identification is straightforward using the TERRATM. All identified phases are well within the performance capabilities of TERRA making this application easy and accurate. The portable TERRA XRD analyzer is an ideal tool for on-site corrosion inspections.