Background

The surface roughness of the root portion of dental implants is important because roughness increases the overall surface area which, in turn, increases the implant’s stability. The metal portions of dental implants often undergo multiple processing stages to increase roughness including blasting, acid etching, anodic oxidation, and polishing. The optimum surface roughness for dental implants is between 1–10 μm. In Japan, dental implant manufacturers are required to verify the measurements of surface roughness using a laser confocal microscope. Failure to have appropriate roughness can lead to poor adhesion of an implant to a patient’s oral cavity.

The Olympus solutions

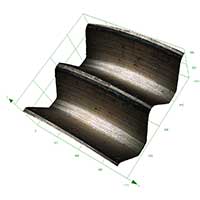

The Olympus LEXT laser confocal microscope offers exceptional accuracy and precision in measuring the roughness of dental implant surfaces. The LEXT’s high resolution and ability to measure steep angles mean that shapes of varying geometry are accurately and precisely measured (Figure 1). The microscope has long working distance objectives so that larger objects, such as dental implants, can be inspected.

Features of the product

The Olympus LEXT gives you the ability to make 3D observations with ultra-high-resolution measurements and a high pixel density. The varying objectives give you the flexibility of having a working distance capable of accommodating larger objects, such as dental implants. The LEXT features high inclination sensitivity for making accurate measurements of complex and steep-sided irregularities.

Image

|  | |

| Figure 1: Dental implant surface measurements using the LEXT | ||