Application

Marking is a technique applied to products or parts for the purpose of identification or traceability. Various marking methods are used including inkjet, laser, and stamping. Metal stamping is a standard method in many industries and involves using a very hard material to stamp a design onto a metal piece. Unlike engraving, stamping leaves a semi-permanent marking without producing chips in the metal. The size or position of each mark affects its visibility while the stamp’s depth affects durability. These marks need to be evaluated to ensure they are in the correct location and stamped to the corrected depth.

The Olympus solution

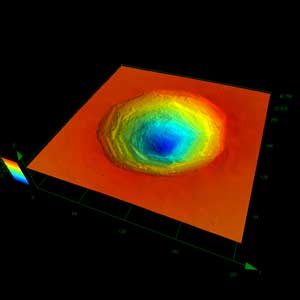

Olympus' LEXT 3D scanning laser microscope utilizes a 405 nm semiconductor laser for high horizontal resolution enabling users to accurately measure the width of a stamped mark. The microscope’s confocal optical system provides accurate three-dimensional data of micron-sized irregularities on a surface. With the LEXT, users can accurately reproduce 3D images and make reliable measurements in the z-axis direction. The stitching function seamlessly combines multiple in-focus images to create a single panoramic image, making it simple to get a complete overview of a marking.

Marking stamped on a metal plate

Objective lens 5X; 5×5 stitching |  Objective lens 20X |  Objective lens 100X, Zoom 1X |

Objective lens 100X, Zoom 1X