Advantages include seamless calibration, increase in throughput, improved ergonomics

What are the benefits of using a fully motorized microscope system? It’s an excellent question and one that can be fully answered when looking at some motorized scope options.

First, let’s look at overall combined benefits. When all components are fully motorized, calibration through your imaging software is seamless. Your software will align the focus point or drift between objectives, allowing the image to stay in focus when changing magnification. The software will also align any XY shift between objectives. This will keep a point of interest that’s in the center of the field of view to remain in the center even when switching between objectives. Your software will physically move the XY location. Your imaging software will also set values to peak performance depending on the imaging method and/or objective lens selection.

Full motorization also results in an overall increase in throughput due to the automation of many imaging techniques and reduced operator skill requirements as the system can be set up through software, allowing for a simplified interface and use. This will also improve repeatability of images and measurements between operators at varying skill levels. Within the software, user access rights can be set so operators who need an engineering-level interface can have and access these functions, while basic operators are set to use a simplified interface.

Additional functions and benefits that come with a fully motorized system include enhanced microscope control and communication, including better control of microscope functions such as observation method (BF, DF, DIC), objective lens selection, lighting conditions, and aperture control. Made possible through software or hand switches, this enhanced control provides a number of benefits to the operator including:

- Guaranteed calibration as the software will have feedback as to which objective lens is in place when the image is captured.

- Simplified microscope configuration setup through observation method selection in software. This allows for all microscope functions to be automatically set for predefined observation conditions. Example: DF condition would set the DF mirror turret, turn the lamp intensity to max, open the aperture stop to max, change to the DF objective lens, and possibly even set a focus point.

- The ability to read and load microscope values from captured images within imaging software (i.e., OLYMPUS Stream™). This allows you to set up the system in the exact same configuration as when the image was taken.

- An increase in ergonomics as operators no longer have to reach up to the microscope to make changes to magnification or image methods.

- An increase in sample cleanliness as users no longer need to reach above the sample to make changes to objective lenses or observation methods.

A fully motorized microscope configuration may look like this:

Fully motorized microscope frame.

- Motorized XY stage (i.e., Prior, LUDL, Marzhauser).

- Motorized Z (focus).

- Motorized add-on Focus drive (if not already included on microscope frame).

- Stage controller (either an external control box or internal PC card).

- Joystick for XY control and possibly Focus control.

- Digital camera for automated image acquisition.

- Control software.

A motorized XY stage provides the following user benefits:

- Ability to perform MIA (Multiple Image Alignment). Allows for large out-of-field-of-view image capture through stitching.

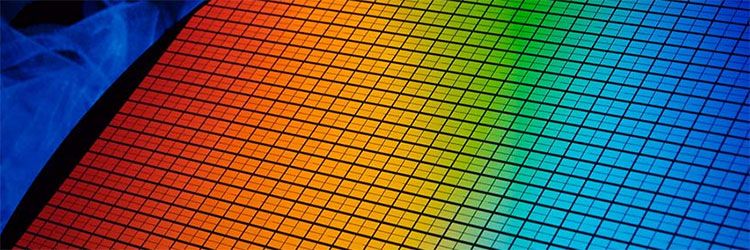

- Ability to set and save location points for return inspection. This is used a lot for inspection points on wafers, semiconductor dies, or circuits.

- Motorized control is very ergonomic as the user can move the joystick to any location or control all stage movement and values through software. You no longer have to reach under or next to the stage to move the sample.

A motorized Z (focus) delivers the following operational enhancements:

- Ability to perform EFI (Extended Focal Imaging). This allows you to capture multiple Z focus images to generate an all-in-focus image. Ideal for samples with great depths or heights.

- Focus maps. When stitching in XY, this added ability will compensate for any sample drift in focus, allowing you to stitch large areas while having your software keep the sample in focus.

- Improved ergonomics as the focus is now motorized, keeping you from having to reach for focus knobs. This is done either with software control or joystick.

Get In Touch