|

The DELTA Line Takes Detection Limits of Residuals in Carbon Steel to an All Time Low!

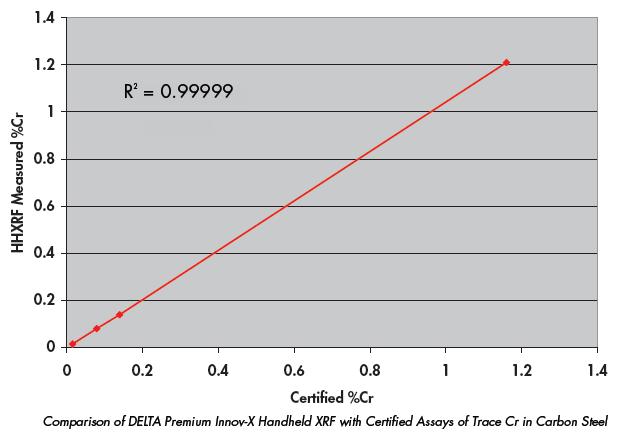

Highly accurate measurements of low levels of Cr, Ni and Cu in carbon steel are critical for predicting accelerated corrosion of components in HF Alkylation process units. It has been shown that if the sum of the residuals, Cr, Ni and Cu, exceeds 0.20%, the carbon steel components used in HF Alkylation processes will likely experience a preferentially accelerated corrosion rate. In general, a level between 0.15% and 0.20% of the sum of the three key residuals is deemed optimal, depending on the component, its use and location in the unit. As this is a decisive measurement for critical, low levels of Cr, Ni and Cu, it is necessary to grind the inspected component with an aluminum oxide disc to remove at least 0.004" of the surface prior to testing. Elbows, tees, reducers, couplings, flanges, welds, caps, plugs and other fittings, as well as pipe-scale can all be tested for the maximum allowable value of the sum of the three key residuals. |  |

| Excellent Accuracy and Low Levels of Detection are Critical for Predicting Accelerated CorrosionIn addition to testing for corrosion indicative residuals, the petrochemical industry depends on HHXRF analyzers for material inspection startups, shutdowns, general maintenance and trouble shooting. Managers cannot afford to depend on out-of-date and unreliable equipment, or untimely support of equipment. They also cannot afford to fall behind the technology curve. The analytical capabilities of HHXRF continue expanding; and, new features enable operators to be more effective and efficient. Upgrade your HHXRF to the DELTA - the latest HHXRF loaded with innovative features and backed by the industry's best service and support. |

| Residual Elements for HF Alkylation Accelerated Corrosion Prediction | |||||||||

| Standard |

Cert

%Cr |

XRF

%Cr |

Error

(+/-) |

Cert

%Ni |

XRF

%Ni |

Error

(+/-) |

Cert

%Cu |

XRF

%Cu |

Error

(+/-) |

| IAMR 229A | 0.015 | 0.015 | 0.002 | 0.029 | 0.028 | 0.006 | 0.072 | 0.073 | 0.008 |

| IARM 28E | 0.079 | 0.080 | 0.005 | 0.145 | 0.139 | 0.013 | 0.030 | 0.028 | 0.002 |

| IARM 33D | 0.139 | 0.139 | 0.006 | 1.78 | 1.777 | 0.03 | 0.014 | 0.013 | 0.003 |

| IAMRM 35F | 1.16 | 1.21 | 0.006 | 0.047 | 0.041 | 0.005 | 0.12 | 0.12 | 0.007 |

| Residual Elements Measured by HHXRF | |||||

| Standard |

XRF

%Cr |

XRF

%Ni |

XRF

%Cu |

Sum of

Residuals (%) |

Inspection

P/F |

| IAMR 229A | 0.015 | 0.028 | 0.073 | 0.116 | Pass |

| IARM 28E | 0.080 | 0.139 | 0.028 | 0.247 | Fail |

| IARM 33D | 0.139 | 1.777 | 0.013 | 1.929 | Fail |

| IAMRM 35F | 1.21 | 0.041 | 0.12 | 1.371 | Fail |

| Residual Elements Certified | |||||

| Standard |

Cert

%Cr |

Cert

%Ni |

Cert

%Cu |

Sum of

Residuals (%) |

Inspection

P/F |

| IAMR 229A | 0.015 | 0.029 | 0.072 | 0.116 | Pass |

| IARM 28E | 0.079 | 0.145 | 0.03 | 0.254 | Fail |

| IARM 33D | 0.139 | 1.78 | 0.014 | 1.933 | Fail |

| IAMRM 35F | 1.16 | 0.047 | 0.12 | 1.327 | Fail |

Handheld XRF for Metals & Alloys Industries

| Iron & Steel | Non-ferrous | Scrap & Secondary |

Iron and steel are the most widely used of metals and alloys. Lighter metals, non-ferrous, newly developed and exotic alloys are also utilized extensively, but iron and steel are considered the basic raw materials for the majority of industrial goods and construction. Although produced from ores mined around the globe, steel is one of the most recycled materials in the world. From base form to recycled materials to finished products, metals and alloys are integral to the fabric of society, the consumption of which is often considered a primary indicator of development and economic progress. | ||

Metals Alloys is a serious, dynamic business.Innov-X is serious and dynamic too. Our DELTA XRF analyzer is an essential tool for all businesses involved in the trade or use of metals alloys. In seconds, you can nondestructively measure 25+ elements. Turnings, shavings, rods, wires, small parts, components, sizeable materials and large structures can all be analyzed directly, non-destructively. How you get them, how you make them, how you use them, how you sell them is how you measure them. Whether you check purity, chemistry, or grade ID for highest value, maximum recovery, quality, conformance, or maintenance and safety, our DELTA XRF analyzer will give you immediate answers to take action on now. Don't wait. Take your metals alloys inspection to the next level with Innov-X! |  |